Foundation Design

Uploaded by

ayazmadFoundation Design

Uploaded by

ayazmadNUCLEAR POWER CORPORATION OF INDIA LTD.

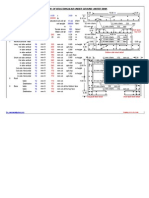

DESIGN OF BI-AXIAL ISOLATED RCC FOOTING (IS 456, 2000) Building Name 2 MW CMCS Room Footing Number: 2, 3, 6, 12, 13, 14, 15 Node number 106, 111, 104, 105, 108, 109, 114 COLUMN Length (l, dim. || Z axis ) = Breadth (b, dim. || X axis) = FOOTING Foot length (L, dim. || Z axis) = Foot Breadth (B, dim. || X axis) = Thickness of footing (t) = Clear cover of footing = Main bar dia of footing = Effective depth of footing dz = Effective depth of footing dx = Selfweight of the footing = Area of Footing(A) = Sect mod of foot about Z axis (Zz) = Sec mod of foot about X axis (Zx) = MATERIALS OF CONSTRUCTION Grade of concrete fck = Grade of steel fy =

530 mm 230 mm Breadth 2.4 m 2.6 2.4 530 50 10 475 465 82.68 6.24 2.50 2.70 m m mm mm mm mm mm KN m2 m3 m3

global X

global Z

global Z global

Length 2.6 m

Footing Dimensions

2 25 N/mm 2 415 N/mm

CHECK FOR GROSS BEARING PRESSURE Safe NET bearing pressure = 103 Safe gross bearing pr. = 148.54 Unfactored load case number = 7 Axial load from output (P1) = 504 Moment about Z axis (Mz) = 45.933333 Moment about X axis (Mx) = 0.9333333 Depth of top of foot. from ground = 2 Unit wt of soil = 18 Weight of soil retained above foot = 220.25 P = (P1+soil+foot self wt) = 806.93 Maximum bearing pressure = 148.06 Minimum bearing pressure = 110.57 Hence footing is safe against max gross bearing pr. DESIGN FORCES Factored load comb. no. Axial load:(Pu) = Moment about Z axis (Muz) = Moment about X axis (Mux) = Maximum effective soil pressure pe max ( Pu/Area+ Muz/Zz + Mux/Zx) = Minimum effective soil pressure pe min

KN/m2 KN/m3 KN KN-m KN-m m KN/m3 KN KN KN/m2 KN/m2

(net pr. + depth of foot * soil unit wt)

M Mx P P M y y M x A A ZZ ZxZx y y

7 756 KN 68.9 KN-m 1.4 KN-m

2 149.28 KN/m

2 ( Pu/Area - Muz/Zz - Mux/Zx) = 93.03 KN/m Design of footing is done using above maximum effective soil pressure

194858335.xls.ms_office

NUCLEAR POWER CORPORATION OF INDIA LTD.

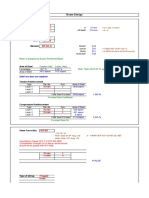

CALCULATION FOR BOTTOM STEEL Mu about X1 X1 = ( pe max x length2/2)=

Ast =

0.5 f ck 4 .6 M u 1 - 1 bd fy f ck bd 2

79.95 KN-m per meter Mulimit = 778.98 KN-m per meter The section is singly reinforced

2 Hence, Ast = 474.302 mm 2 Min Ast = 636.000 mm (0.12 % for slab, cl 26.5.2.1) Spacing (reqd.) = 123.49 mm (considering max of above two calculated values of Ast) pt required = 0.13 % Sp (prov.) = 120 mm Ast (prov.) = Hence required 10 mm dia bar @ 123 mm c/c parellel to length of footing ( || to Z) pt (prov.) = 0.14 % Mu about N1 N1 = ( pe max x length2/2)= 87.87 KN-m per meter 2 Calc. Ast = 533.791 mm The section is singly reinforced 2 Min Ast = 636 mm (0.12 % for slab, cl 26.5.2.1) Spacing (reqd.) = 123.49 mm (considering max of above two calculated values of Ast) pt required = 0.13 % Sp (prov.) = 120 mm Ast (prov.) = Hence required 10 mm dia bar @ 123 mm c/c parellel to breadth of footing ( || to X) Arrangement of bottom reinforcement as per above design is shown below pt (prov.) = 0.14 % 10 mm dia bar @ 120 mm c/c

654.50 mm2

654.50 mm2

10 mm dia bar @ 120 mm c/c

Footing Length 2600 mm

Breadth 2400 mm

Sec 1-1 1005 705 L1 X1 X 230

Z N1 a L2 560 L1 530 Footing Length 2600 mm PLAN X1 X a L2

Z N1

Breadth 2400 mm 610

194858335.xls.ms_office

NUCLEAR POWER CORPORATION OF INDIA LTD.

CHECK FOR ONE WAY SHEAR : One way shear at critical section L1- L1 Distance of critical sec. from edge of footing = 0.56 m Shear force Vu =pe max x 0.56 x 1m width of footing = 2 tv = Vs/bd = Shear stress 0.176 N/mm 2 tc = tc max = 0.280 N/mm tv < tc hence O.K. (Shear chairs not required)

83.594 KN

2 3.1 N/mm

One way shear at critical section L2- L2 Distance of critical sec. from edge of footing = 0.61 m Shear force Vu =pe max x 0.61 x 1m width of footing = 2 tv = Vs/bd = Shear stress 0.192 N/mm 2 tc = tc max = 0.283 N/mm tv < tc hence O.K. (Shear chairs not required)

91.058 KN

2 3.1 N/mm

CHECK FOR TWO WAY SHEAR Ref. cl 34.2.4 and cl.31.6.3 of IS 456 : 2000 Allowable shear stress tv allowable = kstc ks = ( 0.5 + bc) = Hence, ks= tc = 0.25 (fck)

0.5

0.93396 <1 0.93396

2 1.25 N/mm 2 1.16745 N/mm

1.5 tc = 825.72 KN 3420 mm 2 1624500 mm

2 1.875 N/mm

tv allowable = ks x tc = Shear force Vs = 149.275 ( 2.6 x 2.4 - 1.005 x 0.705) = Length of critical section = 2 x ( 1005 + 705) = Area of the critical section (length of critical sec x eff. d ) = 2 Hence shear stress tv = 0.508 N/mm tv < ks tc (Shears chairs not required)

194858335.xls.ms_office

DESIGN OF BI-AXIAL ISOLATED RCC FOOTING (IS 456, 2000) Building Name 2 MW CMCS Room Footing Number: 1, 4, 10, 16 Node number 103, 112, 115, 116 COLUMN Length (l, dim. || Z axis ) = Breadth (b, dim. || X axis) = FOOTING Foot length (L, dim. || Z axis) = Foot Breadth (B, dim. || X axis) = Thickness of footing (t) = Clear cover of footing = Main bar dia of footing = Effective depth of footing dz = Effective depth of footing dx = Selfweight of the footing = Area of Footing(A) = Sect mod of foot about Z axis (Zz) = Sec mod of foot about X axis (Zx) = MATERIALS OF CONSTRUCTION Grade of concrete fck = Grade of steel fy =

450 mm 230 mm Breadth 1.7 m 1.9 1.7 450 50 10 395 385 36.34 3.23 0.92 1.02 m m mm mm mm mm mm KN m2 m3 m3

global X

global Z global Length 1.9 m Footing Dimensions

global Z

2 25 N/mm 2 415 N/mm

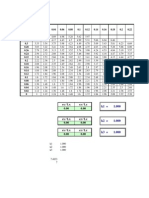

CHECK FOR GROSS BEARING PRESSURE Safe NET bearing pressure = 103 Safe gross bearing pr. = 147.10 Unfactored load case number = 7 Axial load from output (P1) = 240 Moment about Z axis (Mz) = 7.5333333 Moment about X axis (Mx) = 8.2 Depth of top of foot. from ground = 2 Unit wt of soil = 18 Weight of soil retained above foot = 112.55 P = (P1+soil+foot self wt) = 388.89 Maximum bearing pressure = 136.65 Minimum bearing pressure = 104.15 Hence footing is safe against max gross bearing pr. DESIGN FORCES Factored load comb. no. Axial load:(Pu) = Moment about Z axis (Muz) = Moment about X axis (Mux) = Maximum effective soil pressure pe max ( Pu/Area+ Muz/Zz + Mux/Zx) = Minimum effective soil pressure pe min

KN/m2 KN/m3 KN KN-m KN-m m KN/m3 KN KN KN/m2 KN/m2

(net pr. + depth of foot * soil unit wt)

M y Mx P A Zy Zx

7 360 KN 11.3 KN-m 12.3 KN-m

2 135.83 KN/m

2 ( Pu/Area - Muz/Zz - Mux/Zx) = 87.08 KN/m Design of footing is done using above maximum effective soil pressure

CALCULATION FOR BOTTOM STEEL Mu about X1 X1 = ( pe max x length2/2)=

Ast =

0.5 f ck 4 .6 M u 1 - 1 bd fy f ck bd 2

35.70 KN-m per meter Mulimit = 538.68 KN-m per meter The section is singly reinforced

2 Hence, Ast = 253.124 mm 2 Min Ast = 540.000 mm (0.12 % for slab, cl 26.5.2.1) Spacing (reqd.) = 145.44 mm (considering max of above two calculated values of Ast) pt required = 0.14 % Sp (prov.) = 145 mm Ast (prov.) = Hence required 10 mm dia bar @ 145 mm c/c parellel to length of footing ( || to Z) pt (prov.) = 0.14 % Mu about N1 N1 = ( pe max x length2/2)= 36.69 KN-m per meter 2 Calc. Ast = 267.150 mm The section is singly reinforced 2 Min Ast = 540 mm (0.12 % for slab, cl 26.5.2.1) Spacing (reqd.) = 145.44 mm (considering max of above two calculated values of Ast) pt required = 0.14 % Sp (prov.) = 145 mm Ast (prov.) = Hence required 10 mm dia bar @ 145 mm c/c parellel to breadth of footing ( || to X) Arrangement of bottom reinforcement as per above design is shown below pt (prov.) = 0.14 % 10 mm dia bar @ 145 mm c/c

541.65 mm2

541.65 mm2

10 mm dia bar @ 145 mm c/c

Footing Length 1900 mm

Breadth 1700 mm

Sec 1-1 845 625 L1 X1 X 230

Z N1 a L2 330 X1 X a L2

Z N1

L1 450 Footing Length 1900 mm PLAN CHECK FOR ONE WAY SHEAR : One way shear at critical section L1- L1 Distance of critical sec. from edge of footing = 0.33 m Shear force Vu =pe max x 0.33 x 1m width of footing = 2 tv = Vs/bd = Shear stress 0.113 N/mm 2 tc = tc max = 0.279 N/mm tv < tc hence O.K. (Shear chairs not required) Calculations for shear chairs (if required) Vu - tcbd = Vus = -65553 N No. of legs (nos.) 2 2 2 2 2 Bar dia. (mm) 8 8 8 8 8 Asv Spacing of chairs 2 (mm ) (mm c/c) -213.18 -213.18 -213.18 -213.18 -213.18

Breadth 1700 mm 340

44.823 KN

2 3.1 N/mm

100.531 100.531 100.531 100.531 100.531

One way shear at critical section L2- L2 Distance of critical sec. from edge of footing = Shear force Vu =pe max x 0.34 x 1m width of footing = 2 tv = Vs/bd = Shear stress 0.117 N/mm

2 tc = 0.283 N/mm tv < tc hence O.K. (Shear chairs not required)

0.34 m 46.182 KN tc max =

2 3.1 N/mm

CHECK FOR TWO WAY SHEAR Ref. cl 34.2.4 and cl.31.6.3 of IS 456 : 2000 Allowable shear stress tv allowable = kstc ks = ( 0.5 + bc) = Hence, ks= tc = 0.25 (fck)

0.5

1.01111 >1 1

2 1.25 N/mm 2 1.25 N/mm

1.5 tc = 366.99 KN 2940 mm 2 1161300 mm

2 1.875 N/mm

tv allowable = ks x tc = Shear force Vs = 135.828 ( 1.9 x 1.7 - 0.845 x 0.625) = Length of critical section = 2 x ( 845 + 625) = Area of the critical section (length of critical sec x eff. d ) = 2 Hence shear stress tv = 0.316 N/mm tv < ks tc (Shears chairs not required)

global

DESIGN OF BI-AXIAL ISOLATED RCC FOOTING (IS 456, 2000) Building Name 2 MW CMCS Room Footing Number: 5, 11 Node number 101, 102 COLUMN Length (l, dim. || Z axis ) = Breadth (b, dim. || X axis) = FOOTING Foot length (L, dim. || Z axis) = Foot Breadth (B, dim. || X axis) = Thickness of footing (t) = Clear cover of footing = Main bar dia of footing = Effective depth of footing dz = Effective depth of footing dx = Selfweight of the footing = Area of Footing(A) = Sect mod of foot about Z axis (Zz) = Sec mod of foot about X axis (Zx) = MATERIALS OF CONSTRUCTION Grade of concrete fck = Grade of steel fy = CHECK FOR GROSS BEARING PRESSURE Safe NET bearing pressure = Safe gross bearing pr. = Unfactored load case number = Axial load from output (P1) = Moment about Z axis (Mz) =

450 mm 230 mm Breadth 1.3 m 1.5 1.3 400 50 10 345 335 19.50 1.95 0.42 0.49 m m mm mm mm mm mm KN m2 m3 m3

global X

global Z global Length 1.5 m Footing Dimensions

global Z

2 25 N/mm 2 415 N/mm

103 146.20 7 89 2.3

KN/m2 KN/m3 KN KN-m KN-m m KN/m3 KN KN KN/m2 KN/m2

(net pr. + depth of foot * soil unit wt)

Moment about X axis (Mx) = 0.42 Depth of top of foot. from ground = 2 Unit wt of soil = 18 Weight of soil retained above foot = 66.47 P = (P1+soil+foot self wt) = 174.97 Maximum bearing pressure = 96.04 Minimum bearing pressure = 83.42 Hence footing is safe against max gross bearing pr. DESIGN FORCES Factored load comb. no. Axial load:(Pu) = Moment about Z axis (Muz) = Moment about X axis (Mux) = Maximum effective soil pressure pe max ( Pu/Area+ Muz/Zz + Mux/Zx) = Minimum effective soil pressure pe min

M y Mx P A Zy Zx

7 133 KN 0.42 KN-m 2.3 KN-m

2 73.92 KN/m

2 ( Pu/Area - Muz/Zz - Mux/Zx) = 62.49 KN/m Design of footing is done using above maximum effective soil pressure

CALCULATION FOR BOTTOM STEEL Mu about X1 X1 = ( pe max x length2/2)=

Ast =

0.5 f ck 4 .6 M u 1 - 1 bd fy f ck bd 2

10.19 KN-m per meter Mulimit = 410.94 KN-m per meter The section is singly reinforced

2 Hence, Ast = 82.146 mm 2 Min Ast = 480.000 mm (0.12 % for slab, cl 26.5.2.1) Spacing (reqd.) = 163.62 mm (considering max of above two calculated values of Ast) pt required = 0.14 % Sp (prov.) = 160 mm Ast (prov.) = Hence required 10 mm dia bar @ 163 mm c/c parellel to length of footing ( || to Z) pt (prov.) = 0.14 % Mu about N1 N1 = ( pe max x length2/2)= 10.58 KN-m per meter 2 Calc. Ast = 87.887 mm The section is singly reinforced 2 Min Ast = 480 mm (0.12 % for slab, cl 26.5.2.1) Spacing (reqd.) = 163.62 mm (considering max of above two calculated values of Ast) pt required = 0.14 % Sp (prov.) = 160 mm Ast (prov.) = Hence required 10 mm dia bar @ 163 mm c/c parellel to breadth of footing ( || to X) Arrangement of bottom reinforcement as per above design is shown below pt (prov.) = 0.15 % 10 mm dia bar @ 160 mm c/c

490.87 mm2

490.87 mm2

10 mm dia bar @ 160 mm c/c

Footing Length 1500 mm

Breadth 1300 mm

Sec 1-1 795 575 L1 X1 X 230

Z N1 a L2 180 X1 X a L2

Z N1

L1 450 Footing Length 1500 mm PLAN CHECK FOR ONE WAY SHEAR : One way shear at critical section L1- L1 Distance of critical sec. from edge of footing = 0.18 m Shear force Vu =pe max x 0.18 x 1m width of footing = 2 tv = Vs/bd = Shear stress 0.039 N/mm 2 tc = tc max = 0.284 N/mm tv < tc hence O.K. (Shear chairs not required) Calculations for shear chairs (if required) Vu - tcbd = Vus = -84718 N No. of legs (nos.) 2 2 2 2 2 Bar dia. (mm) 8 8 8 8 8 Asv Spacing of chairs 2 (mm ) (mm c/c) -143.53 -143.53 -143.53 -143.53 -143.53

Breadth 1300 mm 190

13.305 KN

2 3.1 N/mm

100.531 100.531 100.531 100.531 100.531

One way shear at critical section L2- L2 Distance of critical sec. from edge of footing = Shear force Vu =pe max x 0.19 x 1m width of footing = 2 tv = Vs/bd = Shear stress 0.041 N/mm

2 tc = 0.288 N/mm tv < tc hence O.K. (Shear chairs not required)

0.19 m 14.044 KN tc max =

2 3.1 N/mm

CHECK FOR TWO WAY SHEAR Ref. cl 34.2.4 and cl.31.6.3 of IS 456 : 2000 Allowable shear stress tv allowable = kstc ks = ( 0.5 + bc) = Hence, ks= tc = 0.25 (fck)

0.5

1.01111 >1 1

2 1.25 N/mm 2 1.25 N/mm

1.5 tc = 110.35 KN 2740 mm 2 945300 mm

2 1.875 N/mm

tv allowable = ks x tc = Shear force Vs = 73.917 ( 1.5 x 1.3 - 0.795 x 0.575) = Length of critical section = 2 x ( 795 + 575) = Area of the critical section (length of critical sec x eff. d ) = 2 Hence shear stress tv = 0.117 N/mm tv < ks tc (Shears chairs not required)

global

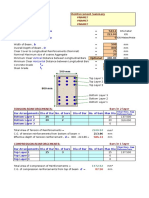

DESIGN OF BI-AXIAL ISOLATED RCC FOOTING (IS 456, 2000) Building Name 2 MW CMCS Room Footing Number: 7, 8, 9 Node number 107, 117, 113 COLUMN Length (l, dim. || Z axis ) = Breadth (b, dim. || X axis) = FOOTING Foot length (L, dim. || Z axis) = Foot Breadth (B, dim. || X axis) = Thickness of footing (t) = Clear cover of footing = Main bar dia of footing = Effective depth of footing dz = Effective depth of footing dx = Selfweight of the footing = Area of Footing(A) = Sect mod of foot about Z axis (Zz) = Sec mod of foot about X axis (Zx) = MATERIALS OF CONSTRUCTION Grade of concrete fck = Grade of steel fy =

600 mm 230 mm Breadth 2.5 m 2.85 2.5 530 50 10 475 465 94.41 7.13 2.97 3.38 m m mm mm mm mm mm KN m2 m3 m3

global X

global Z global Length 2.85 m Footing Dimensions

global Z

2 25 N/mm 2 415 N/mm

CHECK FOR GROSS BEARING PRESSURE Safe NET bearing pressure = 103 Safe gross bearing pr. = 148.54 Unfactored load case number = 7 Axial load from output (P1) = 651.33333 Moment about Z axis (Mz) = 9 Moment about X axis (Mx) = 11.2 Depth of top of foot. from ground = 2 Unit wt of soil = 18 Weight of soil retained above foot = 251.53 P = (P1+soil+foot self wt) = 997.27 Maximum bearing pressure = 146.31 Minimum bearing pressure = 133.63 Hence footing is safe against max gross bearing pr. DESIGN FORCES Factored load comb. no. Axial load:(Pu) = Moment about Z axis (Muz) = Moment about X axis (Mux) = Maximum effective soil pressure pe max ( Pu/Area+ Muz/Zz + Mux/Zx) = Minimum effective soil pressure pe min

KN/m2 KN/m3 KN KN-m KN-m m KN/m3 KN KN KN/m2 KN/m2

(net pr. + depth of foot * soil unit wt)

M y Mx P A Zy Zx

7 977 KN 13.5 KN-m 16.8 KN-m

2 146.63 KN/m

2 ( Pu/Area - Muz/Zz - Mux/Zx) = 127.61 KN/m Design of footing is done using above maximum effective soil pressure

CALCULATION FOR BOTTOM STEEL Mu about X1 X1 = ( pe max x length2/2)=

Ast =

0.5 f ck 4 .6 M u 1 - 1 bd fy f ck bd 2

92.79 KN-m per meter Mulimit = 778.98 KN-m per meter The section is singly reinforced

2 Hence, Ast = 551.983 mm 2 Min Ast = 636.000 mm (0.12 % for slab, cl 26.5.2.1) Spacing (reqd.) = 123.49 mm (considering max of above two calculated values of Ast) pt required = 0.13 % Sp (prov.) = 120 mm Ast (prov.) = Hence required 10 mm dia bar @ 123 mm c/c parellel to length of footing ( || to Z) pt (prov.) = 0.14 % Mu about N1 N1 = ( pe max x length2/2)= 94.45 KN-m per meter 2 Calc. Ast = 574.639 mm The section is singly reinforced 2 Min Ast = 636 mm (0.12 % for slab, cl 26.5.2.1) Spacing (reqd.) = 123.49 mm (considering max of above two calculated values of Ast) pt required = 0.13 % Sp (prov.) = 120 mm Ast (prov.) = Hence required 10 mm dia bar @ 123 mm c/c parellel to breadth of footing ( || to X) Arrangement of bottom reinforcement as per above design is shown below pt (prov.) = 0.14 % 10 mm dia bar @ 120 mm c/c

654.50 mm2

654.50 mm2

10 mm dia bar @ 120 mm c/c

Footing Length 2850 mm

Breadth 2500 mm

Sec 1-1 1075 705 L1 X1 X 230

Z N1 a L2 650 X1 X a L2

Z N1

L1 600 Footing Length 2850 mm PLAN CHECK FOR ONE WAY SHEAR : One way shear at critical section L1- L1 Distance of critical sec. from edge of footing = 0.65 m Shear force Vu =pe max x 0.65 x 1m width of footing = 2 tv = Vs/bd = Shear stress 0.201 N/mm 2 tc = tc max = 0.280 N/mm tv < tc hence O.K. (Shear chairs not required) Calculations for shear chairs (if required) Vu - tcbd = Vus = -37707 N No. of legs (nos.) 2 2 2 2 2 Bar dia. (mm) 8 8 8 8 8 Asv Spacing of chairs 2 (mm ) (mm c/c) -447.61 -447.61 -447.61 -447.61 -447.61

Breadth 2500 mm 660

95.312 KN

2 3.1 N/mm

100.531 100.531 100.531 100.531 100.531

One way shear at critical section L2- L2 Distance of critical sec. from edge of footing = Shear force Vu =pe max x 0.66 x 1m width of footing = 2 tv = Vs/bd = Shear stress 0.204 N/mm

2 tc = 0.283 N/mm tv < tc hence O.K. (Shear chairs not required)

0.66 m 96.779 KN tc max =

2 3.1 N/mm

CHECK FOR TWO WAY SHEAR Ref. cl 34.2.4 and cl.31.6.3 of IS 456 : 2000 Allowable shear stress tv allowable = kstc ks = ( 0.5 + bc) = Hence, ks= tc = 0.25 (fck)

0.5

0.88333 <1 0.88333

2 1.25 N/mm 2 1.10417 N/mm

1.5 tc = 933.64 KN 3560 mm 2 1691000 mm

2 1.875 N/mm

tv allowable = ks x tc = Shear force Vs = 146.634 ( 2.85 x 2.5 - 1.075 x 0.705) = Length of critical section = 2 x ( 1075 + 705) = Area of the critical section (length of critical sec x eff. d ) = 2 Hence shear stress tv = 0.552 N/mm tv < ks tc (Shears chairs not required)

global

You might also like

- Combined Footing Design For Compressive LoadNo ratings yetCombined Footing Design For Compressive Load8 pages

- Material Data:: Foundation For Pipe Support100% (1)Material Data:: Foundation For Pipe Support8 pages

- Name of Work:-Design of Circular Beam: DegreeNo ratings yetName of Work:-Design of Circular Beam: Degree25 pages

- 7.0 Punching Check: 7.1 Punching of Column in Column CapitalNo ratings yet7.0 Punching Check: 7.1 Punching of Column in Column Capital6 pages

- Circular Water Tank With Domcal Top and Flat Base100% (2)Circular Water Tank With Domcal Top and Flat Base20 pages

- Larsen & Toubro Limited: 2206-330Mw Combined Cycle Power Plant at Pillaiperumanallur100% (1)Larsen & Toubro Limited: 2206-330Mw Combined Cycle Power Plant at Pillaiperumanallur6 pages

- Control Room - 2 Way Slab Design-Roof SlabNo ratings yetControl Room - 2 Way Slab Design-Roof Slab152 pages

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Difference Beetween Is 800-2007 & Is 800-1984No ratings yetDifference Beetween Is 800-2007 & Is 800-198496 pages

- 60Ghz Communications LDPC Part 2: 60Ghz (11ad) : André Bourdoux (Circuits and Systems For Ict - Imec)No ratings yet60Ghz Communications LDPC Part 2: 60Ghz (11ad) : André Bourdoux (Circuits and Systems For Ict - Imec)25 pages

- Nabil Mohammed Abdulaal IT Management Professional 3No ratings yetNabil Mohammed Abdulaal IT Management Professional 34 pages

- Hydrostatic Test Procedure For Site & Commissioning HT-031-R1100% (1)Hydrostatic Test Procedure For Site & Commissioning HT-031-R17 pages

- Gabrielle Walden Resume 35mm ProjectionistNo ratings yetGabrielle Walden Resume 35mm Projectionist2 pages

- Ancient Vedic Teaching Program Techniques of Dispercing KnowledgeNo ratings yetAncient Vedic Teaching Program Techniques of Dispercing Knowledge5 pages

- A Short History of M&I Materials Limited and Its Heritage: 1901-2010No ratings yetA Short History of M&I Materials Limited and Its Heritage: 1901-201032 pages

- Minimal PDF: Adobe PDF Specification ("ISO Approved Copy of The ISO 32000-1 Standards Document") TipsNo ratings yetMinimal PDF: Adobe PDF Specification ("ISO Approved Copy of The ISO 32000-1 Standards Document") Tips3 pages

- T10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0No ratings yetT10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 013 pages

- The Source Unleash Your Natural Energy Power Up Your Health and Feel 10 Years Younger 1st Edition Woodson Merrell 2024 Scribd Download100% (1)The Source Unleash Your Natural Energy Power Up Your Health and Feel 10 Years Younger 1st Edition Woodson Merrell 2024 Scribd Download61 pages

- Power Curve of Cummins L300 20 Diesel Engine100% (1)Power Curve of Cummins L300 20 Diesel Engine4 pages

- Detailed Lesson Plan in Science (Simple Machine Lever)No ratings yetDetailed Lesson Plan in Science (Simple Machine Lever)10 pages

- 7.0 Punching Check: 7.1 Punching of Column in Column Capital7.0 Punching Check: 7.1 Punching of Column in Column Capital

- Larsen & Toubro Limited: 2206-330Mw Combined Cycle Power Plant at PillaiperumanallurLarsen & Toubro Limited: 2206-330Mw Combined Cycle Power Plant at Pillaiperumanallur

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental Application

- 60Ghz Communications LDPC Part 2: 60Ghz (11ad) : André Bourdoux (Circuits and Systems For Ict - Imec)60Ghz Communications LDPC Part 2: 60Ghz (11ad) : André Bourdoux (Circuits and Systems For Ict - Imec)

- Nabil Mohammed Abdulaal IT Management Professional 3Nabil Mohammed Abdulaal IT Management Professional 3

- Hydrostatic Test Procedure For Site & Commissioning HT-031-R1Hydrostatic Test Procedure For Site & Commissioning HT-031-R1

- Ancient Vedic Teaching Program Techniques of Dispercing KnowledgeAncient Vedic Teaching Program Techniques of Dispercing Knowledge

- A Short History of M&I Materials Limited and Its Heritage: 1901-2010A Short History of M&I Materials Limited and Its Heritage: 1901-2010

- Minimal PDF: Adobe PDF Specification ("ISO Approved Copy of The ISO 32000-1 Standards Document") TipsMinimal PDF: Adobe PDF Specification ("ISO Approved Copy of The ISO 32000-1 Standards Document") Tips

- T10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0T10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0

- The Source Unleash Your Natural Energy Power Up Your Health and Feel 10 Years Younger 1st Edition Woodson Merrell 2024 Scribd DownloadThe Source Unleash Your Natural Energy Power Up Your Health and Feel 10 Years Younger 1st Edition Woodson Merrell 2024 Scribd Download

- Detailed Lesson Plan in Science (Simple Machine Lever)Detailed Lesson Plan in Science (Simple Machine Lever)